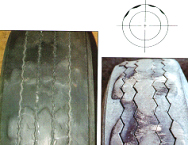

Scalloped – Cupping Damage:

Primary type wear experienced with worn shocks. Loss of shock dampening allows for greater tire load variance and allows build up of resonance with the rhythm of a road quickly resulting in cupping wear. Tire companies can measure early scalloped cupping in new truck tires on older shocks within a few hundred miles on a rough road; however, the same test conducted with new tires and new shocks does not experience similar damage for tens of thousands of miles. This can impact the life of the tire as much as 50%. For this reason, it has been found cost effective to change shocks when replacing tires on modern Heavy Truck suspensions.

River or Channel Wear:

Tests (driven by results of the SAE Study) identified the cause of River Channel Wear due to the loss of shock absorber dampening , allowing excessive footprint distortion. This creates excessive wear along the sides of the tread pattern where the rubber that can move the easiest.

Brake Lock Up Wear:

Worn shocks can contribute to brake lock up causing uneven wear. If the suspension had been in resonance with the rhythm of the road allowing the tires inconsistent road traction, prior to an emergency braking situation, a brake lock up situation can easily occur.